fortera cement, Excellent workability and Performance

regulation ready

For use as a Supplementary Cementitious Material up to 35%

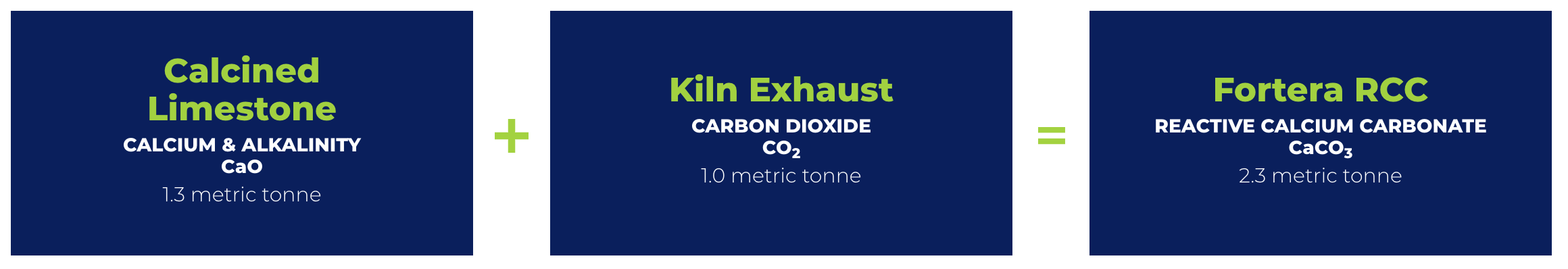

In traditional cement production, 44% of the limestone fed into the process is decomposed into CO₂ almost doubling your limestone mining, grinding, and calcining costs. Since Fortera does not release CO₂, every tonne of feedstock results in one tonne of sellable product, creating an economic advantage.

FORTERA HAS BEEN TIME TESTED

FOR OVER 10 YEARS

IN REAL WORLD APPLICATIONS

FORTERA RECARB™ PROCESS

The Fortera ReCarb™ process re-carbonates Calcium Oxide without losing its cementitious properties. The result is a cementitious mineral that is rich in CO₂.

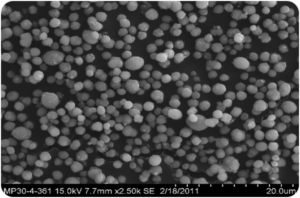

FORTERA MAKES A RARE FORM OF REACTIVE CALCIUM CARBONATE

Reactive Calcium Carbonate (CaCO₃) is naturally formed when Calcium and CO₂ come into contact. In nature, this combination results in a cementitious reaction forming hard materials and robust structures such as shells, rocks, and reefs.

Fortera has developed a process for recreating this natural cement with the ability to stabilize it in a dry powder form only activating its cementitious properties the next time it is wetted.

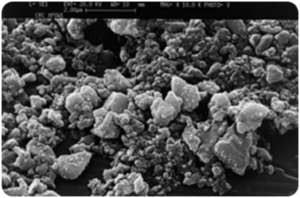

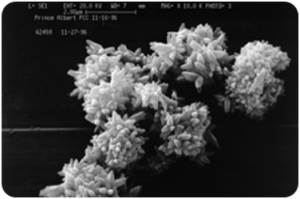

GCC

PCC

Precipitated CaCO₃

FORTERA RCC

Reactive CaCO₃

Our reactive calcium carbonate reacts with water transforming from spherical particles to a complex structural network of rods. This transformation is where Fortera cement gets its hardening and binding ability.

CEMENT IS THE SECOND MOST CONSUMED PRODUCT ON EARTH BEHIND WATER

Big innovations in this space allow for a big impact in the fight against climate change.

A CHANGE EVERYONE CAN GET BEHIND